A Prospectus for

Investment in the

Yogo Sapphire Mines

1959

Date of Offering May 5th, 1959

This Offer Is Made Only to Bona Fide Residents

of the State of Montana

21.862 Shares

THE NEW MINE

SAPPHIRE SYNDICATE

COMMON STOCK

(Par Value-$1.00 per Share)

OFFERING PRICE $12.50 per Share

TRANSFER AGENT

NEVADA AGENCY AND TRUST COMPANY

139 NORTH VIRGINIA ST.

RENO, NEVADA

THE NEW MINE SAPPHIRE SYNDICATE

325 Fratt Building

BILLINGS, MONTANA

No dealer, salesman or other person has been authorized to give any information or to make any representations other than those contained in this prospectus, in connection with the offering contained herein, and information or representation not herein contained, if given or made, must not be relied upon as having been authorized. This prospectus does not constitute an offering or solicitation in respect to these securities to any person who is not a bona fide resident of the State of Montana.

| Price to Public |

Estimated Distribution Cost |

Net Proceeds to Corporation |

|

| Total | $273,275.00* | $54,655.00 | $218,620.00 |

| Per Share | 12.50 | 2.50 | 10.00 |

|

|||

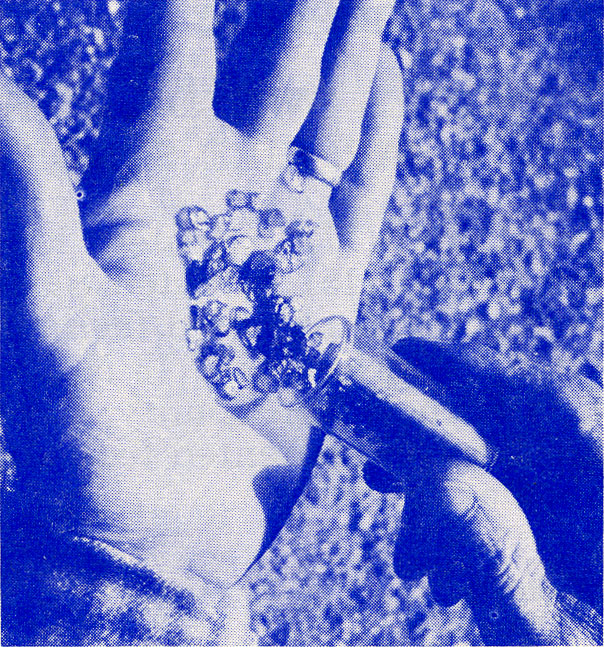

Sapphires from the Yogo deposit in their uncut, unpolished state.

CAPITAL STRUCTURE

THE NEW MINE SAPPHIRE SYNDICATE was incorporated under the laws of the State of Montana in 1898. Its authorized capital is 175,000 shares of common stock with a par value of one dollar each. The Company proposes to sell and issue its remaining unissued 21,862 shares at $12.50 per share to bona fide residents of Montana. The total number of shares then outstanding will be 175,000, the majority of which will be owned by Montana residents. Thus the residents of the State of Montana collectively will own a controlling stock interest in the Company.

BUSINESS

The Company is presently engaged in the business of mining and developing its own properties and marketing sapphires for world wide distribution.

One of the old mine buildings. A portion of the sapphire-bearing dike is shown in the cleft in the hillside in the background.

PROPERTY

PROPERTIES OWNED BY THE NEW MINE SAPPHIRE SYNDICATE

All of seventeen (17) patented lode mining claims, all of fifteen (15) patented placer mining claims and 830 acres of patented fee land, all situated in an area comprised of T 13 N, R 10, 11 and 12 E., M.M., Judith Basin County, Montana, the said mining claims and patented fee land being legally described as follows:

| Name of Patented Lode Mining Claim |

Mineral Survey No. |

|

| Short | 4994 | |

| Gold Cross No. 1 | 4995 | |

| Gold Cross No. 2 | 4996 | |

| Blue Diamond No. 1 | 4997 | |

| Blue Diamond No. 2 | 4998 | |

| Clayberg | 6049 | |

| Gunn | 6050 | |

| Hoover | 6051 | |

| Baker | 6052 | |

| Snowdrift | 6053 | |

| Jewel | 8191 | |

| Kelly | 6237 | |

| Victor | 6238 | |

| Klondyke | 6239 | |

| Hope | 6240 | |

| Gem | 6241 | |

| 4th of July | 6223 | |

| Dud No. 1 | Pat. Placer Mining Claim | 4594 |

| Dud No. 2 | " | 4594 |

| Consolidated | " | 4595 |

| Lincoln | " | 4665 |

| Bar | " | 4665 |

| Grant | " | 4665 |

| Garfield | " | 4665 |

| Divide | " | 4666 |

| Bovette | " | 4666 |

| Gold and Sapphire | " | 5264 |

| Mr. Connell | " | 5265 |

| Flat | " | 8921 |

| Combination | " | 5219 |

| Minna | " | 8221 |

| Line | " | 8222 |

PATENTED FEE LANDS

Lots 3, 6, 7, & 8 of Section 13; Lots 6, 7, 8, & 9 of Section 22; Lots 5, 15 and parts of Lots 10, 12, 13, & 14 of Section 23; S½SE¼ and part of Lot 5 of Section 24, all in T 13 N, R 11 E., M.M.; and E½NW¼, Lots 2, 3, & 4, E½SW¼, SW¼NE¼, and W½SE¼ of Section 18; E½NW¼ and Lots 3 and 4 of Section 19, all in T 13 N, R 12 E, M.M.

GEOLOGY

The geological aspects and ore possibilities of our properties in Judith Basin County, Montana, have been well covered in a comprehensive study in the U. S. Bureau of Mines and well described in U. S. Geological Survey Bulletin No. 983, published in 1952, entitled "Corundum Deposits of Montana." We hereby refer you to a complete reprint of this bulletin pertaining to our properties, which you will find later on in this prospectus. We invite your careful reading of this comprehensive report.

EXPLORATION

Of great importance, however, is our exploration work in 1957–1958, which has apparently proven the existence of the sapphire-bearing dike along a length of some five miles, whereas previously, as indicated in the Bureau of Mines Report, it had been possible only to trace or infer it for this distance. There is no apparent difference between the previously mined portions of the dike and the newly exposed portions. Our pilot operation has proven the existence of gem sapphires in many of the new areas, as well as from the dumps of the older operations, and it now is demonstrated that, as the Bureau of Mines Report states, "Sapphires occur throughout the Yogo Dike."

ORE PROBABILITIES

The "Ore Reserves," or the proportion of the dike that can now be assuredly mined, have been importantly increased as a result of our exploration and testing work. As now revealed, there are some four additional miles of dike that have not been mined, which we believe can now be mined from the surface downward at a minimum expense. The Madison Limestone is reportedly 1,800 feet thick in the area. There is no apparent reason why the dike constituents should change materially as long as it remains within the limestone walls, so, while this hypothesis has not been proven, there is a reasonable probability that the gem-bearing dike may extend to a depth of 1,800 feet for the demonstrated length of five miles.

ORE QUICKLY AVAILABLE

However, for a more conservative estimate of ore reserves, if we assume a depth of merely the 300 feet to which gems have been proven to exist in the old working, and four miles of unworked length, some of which is between worked areas, and an average width of dike of ten feet, a figure of some 2,300,000 cubic yards of gem-bearing dike seems reasonable. Assuming that the dike might be worked to a depth of 100 feet by cheap open-pit methods, some 700,000 cubic yards would be available before underground mining would become necessary. At 30 carats per yard (as indicated by pilot operations), this would produce in excess of 21,000,000 uncut carats of sapphires.

If the mine were worked to a depth of 500 feet, the uncut sapphire production should be well in excess of 100,000,000 carats. In this connection, it should be stated that the dike is wide enough and the walls are firm enough to use modern underground equipment for low cost mining methods.

It is quite evident, without further detail, that there is an abundant and cheap ore supply for our proposed operations.

It likewise seems evident that ore reserves are ample to supply and sustain the gem market with high quality sapphires for the almost unforseeable future.

RECOVERY METHODS

The recovery of sapphires from the dike ore is a relatively simple metallurgical process. The dike material disintegrates upon exposure to the elements, thus eliminating the need for crushing the ore, and the first step in the recovery process is to stockpile the ore, unless it is from near the surface, and allow nature to take its course. After weathering for a year, the ore can then be screened, and the coarse material returned to the stockpile, the fines discarded, and the plus 10 mesh material concentrated to recover the gems. The coarse reject, after weathering, can again be screened, etc.

As for concentration, tests of heavy media separation as well as jigging have given excellent results at low cost and one or the other of these methods, or perhaps a combination of them, seems to assure a high recovery.

Modern equipment can do the job fast and at low cost. However, provision has been made in capital estimates for mining and stockpiling sufficient ore ahead of production requirements in order that the milling department will not be suspended for lack of weathered material to concentrate.

VARIOUS OTHER ITEMS

The supply of water in Yogo Creek is ample for all mining and milling needs, and electric power is available and can be delivered at reasonable cost. Ample and various sites for tailings disposal without danger of polluting streams exist on the property.

CUTTING AND MARKETING

Mr. Dan Grayson, President of New Mine Sapphire Syndicate, who has had many years of experience in merchandising and sales promotion, is in direct charge of the marketing program. During 1958, intensive experimentation in cutting and research in marketing was carried out under his direction. A principal agent, Mr. L. W. Zerner of Lugano, Switzerland, has been selected. Mr. Zerner has had 35 years of experience in the gem field. For 27 years, he operated in Bangkok, Siam, as a gemologist, cutter and merchant. Jointly they have developed a sales, processing and cutting plan to sell both rough and cut stones. Sales sub-agents have been tentatively selected in Bangkok, Siam; Jaipur, India; Zurich, Switzerland; Idar-Oberstein, Germany; Paris, France; London, England and New York, New York.

YOGO SAPPHIRE DEPOSIT

(In the State of Montana)

Reprinted from Pages 6 to 34 of

United States Geoloqical Survey Bulletin No. 983.

Authored by Stephen E. Clabaugh—Published in 1952.

YOGO SAPPHIRE DEPOSIT

INTRODUCTION

The Yogo sapphire deposit is the most important gem locality in the United States. Cut sapphires of excellent quality, valued possibly at as much as $20,000,000 to $30,000,000 have been produced from the deposit, and reserves of sapphire-bearing material are probably adequate to supply several times the quantity mined. Most of the mining was done by a British syndicate which suspended operations in 1929. All rights to the deposit are still held by the syndicate.

The deposit is not well known, and it has never received detailed study. A few descriptions have been published, most of them during the period 1895–1900. The locality is visited occasionally by a few tourists, mineralogists, geologists, and members of the mining profession. Many of these persons have been guests of Charles T. Gadsden, local manager of the New Mine Sapphire Syndicate, and Mrs. Gadsden, who have resided at the property since about 1900. The writer is particularly indebted to the Gadsdens, both for their hospitality on numerous occasions, and for the wealth of information supplied by Mr. Gadsden and incorporated in the pages that follow.

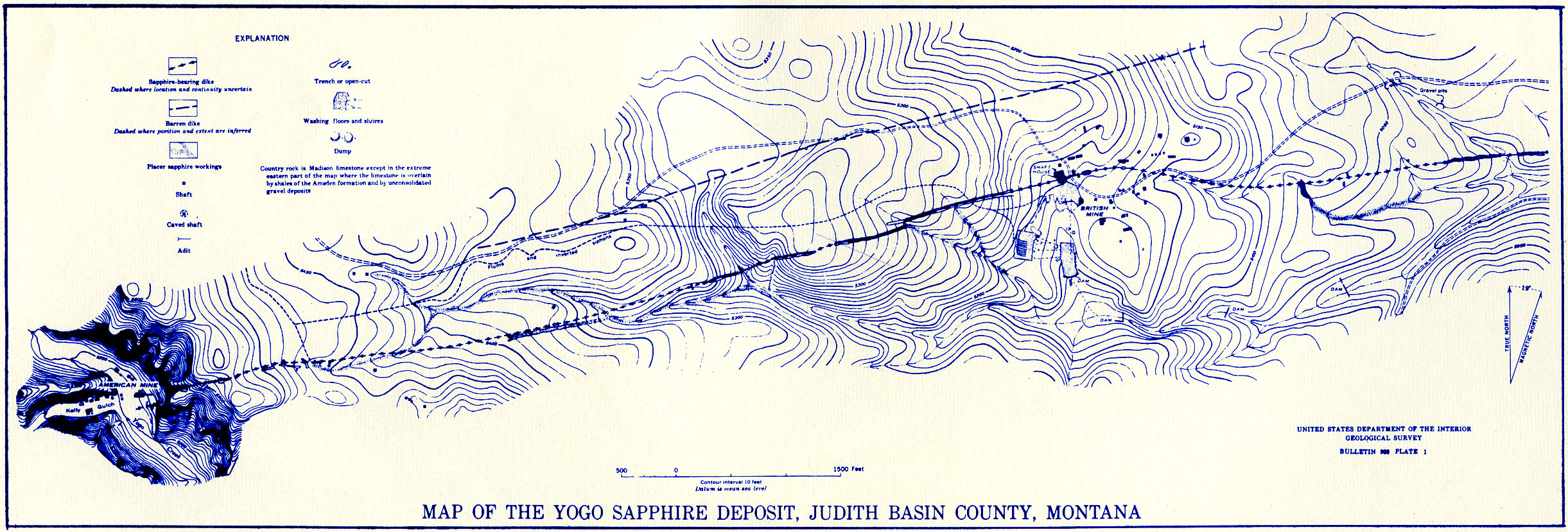

The Yogo sapphire deposit is located in Judith Basin County, 10 to 15 miles southwest of the small town of Utica, and approximately 45 miles southwest of Lewistown. The British mine may be reached over 13 miles of improved dirt road from Utica. The abandoned American mine on Yogo Creek is no longer accessible by road. The sapphire-bearing dike has been traced for a distance of more than 4 miles in an essentially east-west direction. Lode claims, placer claims, and agricultural lands owned by the New Mine Sapphire Syndicate are shown on the property map, figure 2.

Figure 2.—Property map of the New Mine Sapphire Syndicate. Judith Basin County, Mont.

The sapphire-bearing dike occurs at the northeastern margin of a rough, mountainous region, at an elevation of about 5,000 feet. To the east and north are broad valleys, open grassland, farms, and low hills. About 10 to 15 miles west and south of the deposit, the peaks along the crest of the Little Belt Mountains rise to elevations of 8,000 to 9,000 feet. The region to the northeast is semiarid, suited to cattle raising and wheat production by dry farming methods. The mountainous region to the southwest is sparsely inhabited. A few ranches are located in the valleys, and there is sporadic activity in some of the old mining camps. Growths of timber cover most of the mountain slopes.

Along the eastern two-thirds of its extent the sapphire-bearing dike is in an open, rolling, grassland (fig. 3) with occasional forested valleys and low hills, increasing in elevation westward to the heights above Yogo canyon. The western part of the dike is in the rough canyons of Yogo and Kelly Gulches, where limestone cliffs rise abruptly several hundred feet above the canyon floor (figs. 4 and 5). The topography is shown in detail on the plane-table map of the deposit, plate 1.

Figure 3.—View eastward along the old open-cuts of the British sapphire mine, Judith Basin County, Mont.

GEOLOGY

The geology of the Yogo sapphire deposit is exceedingly simple. A nearly vertical sapphire-bearing igneous dike cuts through gently dipping limestone. Corundum has not been found in other igneous rocks of the region. Surface exposures of the dike rock are very poor, for it weathers more readily than the adjacent limestone.

GEOLOGIC SETTING

Sedimentary rocks exposed in the vicinity of the sapphire deposit are massive limestones of the upper part of the Madison limestone of Mississippian age and varicolored shales of the Amsden formation of Mississippian and Pennsylvanian age. At its eastern end the sapphire-bearing dike cuts shaly rocks overlying the Madison limestone; throughout the remainder of its surface extent the dike is in contact with limestone. The Madison limestone is 1,800 feet thick in this area according to Weed (1899, p. 9). The upper part of the formation, well exposed along Yogo Gulch (figs. 4 and 5), consists of massive limestone with indistinct bedding and infrequent shaly layers. The lower and middle parts of the formation are relatively thin bedded and contain more numerous beds of shale or clay. Older sedimentary rocks are exposed west and south of the sapphire deposits. They include dark limestone and shale of Devonian age and limestones, shales, conglomerates, and quartzites of Ordovician and Cambrian age. The Cambrian sedimentary rocks rest on argillites, quartzites, and impure limestones of the pre-Cambrian Belt series and these, in turn, lie on older gneisses and schists. Younger sedimentary rocks crop out northeast of the sapphire deposit in the broad basin through which the Judith River flows .

Figure 4.—View westward into the mouth of Kelly Gulch from the crest of the east wall of Yogo Gulch. Dumps of old mine workings may be seen along the northern margin of the valley floor behind the row of deserted houses. Judith Basin County, Mont.

A wide variety of igneous rocks has been described from the region immediately west of the sapphire deposit in the Little Belt Mountains. Lamprophyric rocks are common in small dikes and sills, and the sapphire-bearing dike probably belongs to this group. According to Pirsson (1900, p. 553):

It has evidently a close affinity with the minettes and shonkinite of the region, and is clearly of the same magma. It has the same richness in biotite and pyroxene as these, but differs in the feldspathic component. Yogo Peak, with its shonkinite, is but a small number of miles distant from the locality.

Most of the igneous rocks in the area are believed to be of Tertiary age. Direct evidence indicates only that the sapphire-bearing dike is post-Pennsylvanian.

A second dike, evidently similar in mineralogy to the one in which gems are found, occurs about 600 feet north of the sapphire dike. No fresh rock is exposed at the surface. Partly altered fragments from prospect pits consist chiefly of augite and biotite. Weed (1900, p. 459) states that "The rock and its debris show no sapphires, although many cart loads of the dirt have been washed from different points along the outcrop." Sapphires have not been reported from any other rocks of the region.

Figure 5.—East wall of Togo Gulch as seen from the valley of Kelly Gulch. The cleft in the limestone cliff marks the fracture zone along which the sapphire-bearing dike was emplaced. Judith Basin County, Mont.

SAPPHIRE-BEARING DIKE

Lode and placer claims were located along the length of the dike as far as it could be traced, a distance of almost 5 miles. (See fig. 2.) Exposures at both ends were chiefly in small prospect pits which have since caved. The central part of the dike and all major workings are shown on the plane-table map, plate 1. The average strike of the dike is about S. 75° W., but as the map shows, it does not follow a straight course. The dip is nearly vertical as indicated by the walls of the old surface workings. (See fig. 3.) C. T. Gadsden reports, in an oral communication, that the average width of the dike in the mine workings was approximately 8 feet and the maximum width more than 20 feet.

The dike rock weathers readily under surface conditions, so that there are no natural exposures of the igneous rock. Weed (1899, p. 9) observed that "the course of the fissure can be traced by a grassy depression in the bare limestone surface, which is dotted with badger and gopher heapings. One of the heapings yielded several hundred carats of gems and was the direct cause of the discovery of the dike." Near the surface the dike rock is altered to a soft, yellow to gray clay surrounding innumerable rough boulders and fragments of yellow- and brown-stained limestone. At greater depth, 5 to 50 feet below the surface, the altered dike rock consists partly of a greenish-gray, friable rock and partly of blue clay, with residual masses of hard, relatively unaltered igneous rock. Locally the dike is dominantly limestone breccia cemented by a subordinate amount of igneous rock, and at no place is the dike rock free of small inclusions of limestone and other rocks.

Plate 1.—Map of the Yogo Sapphire Deposit, Judith Basin County, Montana. (Click to enlarge)

The combination of soft, altered dike rock and residual boulders of hard, nearly fresh igneous rock was found at all depths in the underground workings. The proportion of unaltered to altered rock 250 to 300 feet below the surface is not notably different from that near the surface, according to Gadsden. The alteration may have been produced in part by hydrothermal solutions, or it may have been accomplished almost exclusively by underground water of meteoric origin. The water table lies far below the surface in the underlying Madison limestone, certainly well below the lowest mine workings, which are relatively dry.

No major faults cut the dike, which is relatively uniform in attitude throughout its known length. Locally the dike is choked with limestone fragments and is narrow or absent; at one point it jogs abruptly as if displaced about 50 feet by a transverse fault, but Gadsden states that the dike is continuous below the surface at this point. Another irregularity in the trend of the dike occurs between the main shaft and the limestone cliff at the American mine on the east side of Yogo Creek. Sterrett (1908, p. 820) described the dike at this locality as follows:

The outcrop of the dike in the foot of the canyon wall was not at first located, since it was rather indefinite and was partly covered with large blocks of talus. A crosscut tunnel was driven from the north side until the dike was located, and from this the main drift was carried eastward on the one side, and the dike traced to its outcrop in the canyon wall on the other. A large body of pay rock, apparently over 45 feet wide, was located by the cross cut and drift. Though the relation of this ore body. to the dike was not definitely known at the time or the writer's visit, it seemed to cut across the regular dike with a dip of about 40. to the east. No definite banging wall had been located, though the pay streak was about 12 feet thick from the footwall. This body of ore had been brecciated and the broken masses squeezed into slickensided lenses.

In most exposures of the dike walls, corresponding limestone beds lie opposite each other without appreciable offset, although commonly tilted at slightly different angles. In a few places a vertical offset of a foot or less could be determined. The walls are well exposed in the surface cuts, even in cuts of considerable depth that have stood open for as much as 50 years. (See fig. 3.) Adjacent to the altered dike the limestone is fractured and discolored with yellow and brown stains, but no contact metamorphic effects were noted.

Description of the igneous rock is based on examination of boulders and fragments of relatively fresh, hard material discarded during mining operations. The most readily apparent characteristics of the rock are its dull-gray or greenish-gray color, fine texture except for scattered flakes of dark-brown biotite several millimeters in diameter, and a spotted appearance due to the abundance of inclusions. The inclusions are chiefly white limestone fragments, and they range in size from minute grains to boulders. Small inclusions, less than 1 centimeter long, are especially abundant in some parts of the rock. When exposed to the weather for a number of years the firm dike rock gradually breaks down to gray-green sand and clay filled with innumerable small flecks of biotite.

Microscopic examination of the rock shows that it is made up chiefly of pyroxene and biotite in grains that average less than one-fourth millimeter in maximum diameter. The larger biotite flakes, which are noted in hand specimens, make up less than one percent of the volume of the rock. In his description of the rock Pirsson (1897, pp. 419–420) wrote as follows:

The biotite is strongly pleochroic, varying between an almost colorless and a strong, clear, brown tint. It occurs in ragged masses, rarely showing crystal outline, and it contains a large amount of small apatite crystals. The pyroxene is of a pale green tint with the habit of diopside and is filled with many inclusions, now altered but probably originally of glass; in some crystals these inclusions are so abundant as to render the mineral quite spongy. The grains sometimes show crystal form but are mostly anhedral and vary in size, though the evidence is not sufficient to show two distinct generations.

These two minerals lie closely crowded together and no feldspars are seen in the rock. The interstices between them consist of a small amount of a clouded, brownish, kaolin-like aggregate, which appears to represent some former feldspathoid component, possibly leucite, perhaps analcite. The rock appears to have its closest affinities in the monchiquite group, of which it may be considered a basic, somewhat altered type. The abundance of biotite shows its relation to the minettes, but the rock is much richer in the ferromagnesian components and lacks the feldspar of the minettes.

In a similar description published at a later date Pirsson (1900, p. 553) classed the rock as an altered analcime basalt.

A chemical analysis of the sapphire-bearing dike rock was prepared in 1950 by Eileen K. Oslund of the Rock Analysis Laboratory, University of Minnesota. The analysis and the calculated normative mineral composition, both calculated as percent by weight, are as follows:

| Chemical analysis of sapphire-bearing dike rock | ||||

| SiO2 | 38.54 | | | ZrO2 | 0.00 |

| Al2O2 | 11.73 | | | P2O5 | 1.18 |

| Fe2O3 | 3.33 | | | Cl | .07 |

| FeO | 3.58 | | | S | .18 |

| MgO | 11.30 | | | Cr2O3 | .10 |

| CaO | 15.60 | | | MnO | .14 |

| Na2O | 1.00 | | | SrO | .13 |

| K2O | 2.32 | | | BaO | .14 |

| H2O+ | 2.33 | | | _____ | |

| H2O– | 1.34 | | | 99.90 | |

| CO2 | 5.56 | | | Less O equiv to S and Cl | .09 |

| TiO2 | 1.06 | | | _____ | |

| | | 99.81 | |||

| Calculation of normative minerals | ||||

| Percent by weight |

Percent by weight |

|||

| orthoclase | 12.2 | | | magnetite | 5.7 |

| leucite | 3.0 | | | ilmenite | 2.3 |

| nepheline | 6.0 | | | apatite | 3.2 |

| anorthite | 23.8 | | | _____ | |

| diopside | 28.9 | | | 100.3 | |

| olivine | 15.2 | | | ||

The norm was calculated after deducting from the analysis the CO2, H2O, Cl, S, and 3.5 percent CaO. The CO2 was assumed to be present in secondary calcite and in limestone inclusions, but only half of the CaO equivalent to CO2 in the calcite was assumed to be of foreign origin; the other half possibly was derived from calcium-bearing minerals in the original igneous rock.

The calculated mineral content of the rock does not approximate the actual mineralogic composition, which is approximately as follows (excluding calcite and dolomite):

| Percent by volume |

|

| Pyroxene | 50 |

| Biotite | 20 |

| Analcime and matrix | 25 |

| Others | 5 |

Among other minerals are the following: apatite, magnetite, zircon, hematite, feldspar, spinel, aegirite-diopside, and fibrous zeolites. Calcite and dolomite are abundant in the rock, chiefly in limestone fragments, veinlets, cavity fillings, and small irregular stringers replacing pyroxene.

In accordance with the Johannsen quantitative mineralogical classification of igneous rocks (Johannsen, 1939, pp. 141–161) the Yogo dike rock may be assigned the number 3125. Typical monchiquite and analcime basalt also fall in Johannsen's family 25 (Johannsen, 1938, pp. 310–395), but both contain olivine and a smaller portion of the dark minerals than the Yogo rock. A number of similar rocks have been described and given varietal names; the most nearly equivalent are certain basic dikes designated ouachitite by Kemp (1891, pp. 392–398), which, however, are markedly porphyritic.

The diopside of the sapphire-bearing dike occurs in crystals of varied size. Most of the crystals are between 0.1 and 0.4 millimeter in diameter, but larger grains are common and a few reach a length of more than 5 millimeters. Some of the larger crystals occur as irregular grains in clusters as much as 1 centimeter in diameter, but most of the crystals tend to be euhedral except where crowded together. They are approximately equidimensional and colorless or very pale green in thin section. The outer parts of the crystals show moderate zoning with distinctly more yellow-green color at the margins. Many grams are partly replaced by calcite or dolomite in small irregular stringers and patches, and swarms of minute inclusions are common. The optical properties of the pyroxene from a crushed fragment of the rock are as follows:

Optically+

2V = 58-60° (measured on the universal stage )

α = 1.685±0.003

β = 1.695±0.003

γ = 1.710±0.003

Z ∧ c = 50°

Pyroxene from one of the larger aggregates of irregular grains was found to have slightly lower indices of refraction,

α = 1.67G±0.003

β = 1.685±0.003

γ = 1.705±0.003

The optical properties indicate that the pyroxene is dominantly diopside (about 70 to 85 percent by weight) and hedenbergite, or more likely diopside, hedenbergite, and aegirite, with the aegirite content higher in the marginal zones, adjacent to interstitial analcime. The extinction angle, (Z ∧ c) of the marginal zone is about 60°. A few small elongate bright-green crystals of aegirite-diopside occur with the larger aggregates of analcime.

Most of the biotite occurs in small grains that average 0.15 to 0.20 millimeter in length and 0.05 to 0.10 millimeter in width. Larger flakes are scattered sparsely through the rock. The smaller grains are strongly pleochroic in thin section, with X = nearly colorless, Y and Z = reddish brown to greenish brown. The larger crystals show a distinct inner zone with less pronounced pleochroism; X = colorless, Y and Z = pale yellowish brown. The refractive indices of the biotite are somewhat varied; average values are approximately as follows:

α = 1.58

β & γ = 1.61–1.62

The biotite probably contains slightly more magnesia than iron oxides.

The material listed as analcime and matrix is the interstitial "clouded, brownish, kaolin-like aggregate, which appears to represent some former feldspathoid component" noted by Pirsson (1897, p. 420). Part of the interstitial material is clear to slightly clouded analcime, which occurs also in a few larger, rounded and irregular grains or clusters and at the margins of some calcite aggregates. The refractive index of the analcime is about 1.485 to 1.490, and the larger grains exhibit faint, patchy anisotropism. Calcite is abundant in the interstitial material and locally cancrinite and fine-grained aggregates of fibrous zeolite (?) are present. But about half of the interstitial material is an extremely fine-grained, clouded aggregate of undetermined composition.

Magnetite is scattered through the rock in innumerable small equidimensional crystals that average about 0.05 millimeter in diameter. They are most abundant in the fine-grained mineral aggregates and interstitial material. Small crystals of apatite are common, especially as inclusions in biotite. Apatite is partly decomposed to soluble phosphates in the altered dike rock, and tailings from the sapphire operations promoted luxuriant growth of grain and vegetables when spread over farmland below the British mine.

Weed (1900, p. 457) observed that the altered dike rock "contained a few hexagonal crystals, which had the form of corundum, but consisted of some decomposition product and showed no trace of the original mineral." These crystals are rare, but they can be found in the fresh dike rock as well as in the weathered material. The crystals are commonly 5 to 15 millimeters in length and the width is about half the length; they have a dull red-brown surface and rough or rounded ends. All are completely altered and consist for the most part of fine-grained, cloudy dolomite and quartz. They are not hex-agonal, but probably orthorhombic or monoclinic with pinacoid (010) and prism (110) faces. The angles between the faces, which could be measured only roughly, are about 50° between prism faces (110 ∧ 110 [macron over second 1]) and 65° between prism and pinacoid (110 ∧ 010). One of the altered crystals was found surrounded by an aureole of diopside as wide as the crystal; others were observed in direct contact with the surrounding igneous rock. It is difficult to suggest conditions under which crystals, either phenocrysts or inclusions, could be altered completely to quartz and carbonate while enclosed in relatively fresh feldspathoid-bearing igneous rock.

The most common inclusions in the dike are limestone fragments, which occasionally show evidence of reaction in the form of a narrow rim of green diopside, but inclusions of other rocks are not uncommon. Weed (1899, p. 9) noted inclusions of quartz, calcite, and pyroxene which "undoubtedly represent altered fragments of the sedimentary rocks carried up in the molten mass at the time the dike was formed." The writer found several small inclusions of a rock that consists of kyanite, quartz, and calcite. Most of the calcite appears to be secondary, like that in the igneous rock. The kyanite is blue, similar in color to some of the pale Yogo sapphires, and it occurs in crystals 2 millimeters or less in length. It is not as abundant as quartz in the granular inclusions. Marginal grains of kyanite have reacted with the lamprophyric magma to produce clots and rims of dark-green spinel. The spinel occurs as clusters of extremely small crystals joined together in mosslike, dendritic aggregates, associated with fine-grained, olive-green biotite and an almost opaque brownish-black mineral. Small, colorless needles of an unidentified mineral project into the margins of several of the kyanite grains adjacent to the spinel rim. An irregular border of small feldspar crystals in semiradial groups separates most of the quartz from the enclosing dike rock. The feldspar occurs in small elongate or platy crystals that show indistinct Carlsbad twinning, wavy extinction, and refractive indices lower than that of balsam. A few grains have cores with distinct polysynthetic twinning and higher refractive indices. Most of the feldspar thus appears to be albite or anorthoclase (?) with oligoclase or even andesine in the cores of a few grains. No corundum was observed in the reaction zone.

SAPPHIRES

DISTRIBUTION

Sapphires occur throughout the Yogo dike. Gadsden reports that they were found to be almost equally abundant in all parts of the workings, and the writer was able to find small sapphires embedded in the dike rock wherever it was exposed. Sterrett (1908, p. 817) notes that the sapphires occur only in the igneous rock, "none having been observed associated with the limestone inclusions." Kunz (1901, p. 756) reported that the quantity of sapphires in different parts of the dike varied widely. Sterrett (1908, p. 818) observed and explained the variation in sapphire content as follows:

Nearly barren places occur in the dike where the latter seems to be choked with limestone, between the fragments of which there is but little dike material. The barren places commonly occur where the dike pinches down to smaller dimensions, which changes in size were doubtless caused by the jamming of limestone fragments included in the magma in the narrower parts of the fissure at the time of the intrusion.

ABUNDANCE

Weed (1900, p. 457) wrote that at the time of his visit to the British mine (about 1895), "some 20 loads, each approximately a square [cubic ?J yard of earth, gave between 1,200 and 1,500 carats of cuttable stones." Kunz (1897, p. 420) says that "Several thousand carats were taken out in 1895, from a preliminary washing of one hundred loads of the 'earth'; of these, two hundred carats were of gem quality and yielded, when cut, sixty carats of fine stones * * *" No accurate record of sapphire recovery in terms of carats per ton of dike rock is available and it is doubtful that records of this type were kept. The figure given by Weed (1899, p. 9), 60 to 75 carats per cubic yard (somewhat more than 1 ton of loose material), is probably too high for an average. From incomplete production records the writer estimates that the average yield was between 20 and 50 carats per ton of dike rock.

SIZE AND COATING

Most of the sapphires from the Yogo deposit are small; crystals or fragments weighing more than a few carats are extremely rare, and the majority of the cut stones weighed less than one carat. The largest sapphire from the deposit weighed 19 carats, but it was tabular in form and the largest of four signet-ring sets cut from it weighed only 8½ carats. One of the most valuable sapphires from the deposit was found in 1919, according to Stoddard (1922, p. 170). The stone was cut and sold in Hatton Garden, London, for £400. It weighed 10 carats in the rough and carats after cutting. The small size of the Yogo gems is commonly said to be a major reason for the closing of the mines in 1929. Not infrequently a whole year passed without the reported discovery of any stone larger than 3 or 4 carats, but Gadsden states that several sapphires of about 12-carat weight were found and that no record was made of many other stones that weighed 5 to 8 carats. He was informed by the London office that in 1921 one 6.25-carat sapphire yielded an excellent 3.40-carat cut stone which was sold for £40 a carat.

Although industrial sapphires were only a byproduct of gem mining, they made up a large proportion of the total production. More than 75 percent by weight of the sapphires recovered from the Yogo deposit, chiefly crystals of small size and thin tabular form, were sold as industrial material.

Sapphires in place in the relatively fresh dike rock are invariably coated with a thin layer of hard black material, a fraction of a millimeter in thickness. Under the microscope this film appears to be an extremely fine grained aggregate consisting mainly of dark-green spinel. The identity of the spinel was checked with X-ray powder photographs. This spinel rich margin is similar to the reaction border around kyanite inclusions (see p. 17), and in both examples the spinel evidently resulted from reaction of the magma with the aluminous mineral. Further evidence of the reaction between sapphires and magma is found in the etched, pitted, and rounded surfaces of the crystals. The natural etching has destroyed the original crystal faces of most of the sapphires, but it rarely progressed far enough to destroy completely the general form and outline.

Figure 6.—Yogo sapphire crystals.

CRYSTALLOGRAPHY

[Editor's Note: In this section, most four-numeral combinations and sets, e.g., 3032, 1017, were printed with macrons (overlines) atop the penultimate numeral or set (as in 4·1·5·20), with the exception of 0001. See Figure 6, above.]

Using a contact goniometer, Pratt (1906, pp. 113-115) identified two crystal forms on Yoga sapphires, the basal pinacoid (0001) and a rhombohedron (3032) that intersects the base at an angle of about 67°. A on figure 6 is similar to Pratt's drawing of an idealized crystal showing these forms about equally developed. Etch pits on the basal pinacoid were found by Pratt to be bounded by rhombohedral planes parallel to the crystal form {1017}, often in combination with plane surfaces parallel to the basal pinacoid. Several of the types of etch pits shown diagrammatically by Pratt are combined here in B on figure 6.

The writer was able to identify a number of crystal forms on Yogo sapphires by studying selected small crystals on the reflecting goniometer. Several forms could be identified only tentatively, and it was often difficult or impossible to distinguish between remnants of original faces and plane surfaces developed by the etching process. Reflections were generally poor and confused due to the etch pits and curved surfaces. Most of the smaller crystals are platy, with their least diameter along the c axis. None exhibited the rhombohedron {3032} found by Pratt on larger crystals, but several showed a combination of two or three rhombohedrons that intersect the basal pinacoid at lesser angles. The unit rhombohedron, {1011}, as shown in combination with the base in C on figure 6, is a common form, as is the low-angle rhombohedron, {1017}. The most prominent face on several small crystals is an intermediate rhombohedron, {1012}, usually in combination with the other two, D on figure 6. All three rhombohedrons appear to be original crystal faces. On the very thin crystal (E on fig. 6) only the rhombohedron {1017} and the basal pinacoid, {0001}, were observed. The low-angle rhombohedron could not be identified with absolute certainty due to poor reflections. Measured rho angles generally fell between 10° and 13°, and the best values were slightly greater than 12°. The calculated rho angle for form {1017} is 12°41'. As mentioned above, Pratt found etch faces that he assigned to the same crystal form. In all the crystal drawings on figure 6 the crystals have been tilted toward the observer less than the customary amount (about 5° instead of 9°), so that a face of the rhombohedron {1017} may be seen on the lower side of the crystals on which it occurs.

F on figure 6 is a diagram showing repeated growth of a rhombohedron and basal pinacoid on the base of a crystal.

Pratt noted on one crystal two very small faces which he judged to be faces of a second-order dipyramid. The writer found several second-order dipyramids among the plane surfaces developed by natural etching. They include the following: {2243}, {2249}, {4489}, and possibly {1126}. On a number of small crystals, faces of the form {2243}, which is common on corundum, appear to be remnants of original faces, partly destroyed by etching. On one well-developed crystal the form {4489} appears to be an original face, also {2243}; and possibly {2249}. Although many of the faces of this crystal are small and deeply etched, the observed and calculated rho angles are in good agreement for the three dipyramids, The average rho angle measured from faces of form {2243} is 60°50'; the calculated angle is 61°11½'. The average measured angle for {2249} is 31°00' and the calculated angle is 31°13'; the measured angle for {4489} is 50°50', and the calculated value is 50°29'. G on figure 6 is an idealized drawing of a crystal showing the 3 second-order dipyramids in combination with two rhombohedrons and the basal pinacoid. Natural crystals are so rounded and pitted by etching that none of them can be expected to exhibit any marked similarity to this figure. Many natural crystals, however, are recognizably similar to A, C, and F on figure 6.

Crystal planes or faces developed by the natural etching of the sapphires in the magma include all of the rhombohedrons and dipyramids mentioned above, the scalenohedrons {3254}, {4·1·5·20}, and {4265}, and traces of a few other forms which could not be identified with any degree of certainty.

FRACTURE AND SPECIFIC GRAVITY

Yogo sapphires are entirely free of the parting planes and twinning commonly observed in corundum from many other localities. Crystals from the Yoga dike break with a distinct conchoidal fracture exposing fresh, glassy surfaces. The absence of partings undoubtedly increases the suitability of the stones for cutting into gems.

The specific gravity of a number of small, clear, unfractured crystals of Yogo sapphires was determined by use of a Berman precision balance. Only values that could be checked by repeated measurements were retained. Bright-blue crystals were found to have the highest specific gravity, but the differences between the stones of different colors were small and perhaps not significant. Values obtained using blue crystals ranged from 4.001 to 4.013. Nearly colorless crystals appeared to have slightly lower specific gravity, with an average value near 4.000. Reddish-purple sapphires gave consistently lower figures that averaged about 3.980, but only a few crystals and fragments of the purple material were available, and the purple sapphires generally possessed a greater abundance of minute fractures and dark-brown inclusions (probably rutile) than the blue and colorless sapphires:

COLOR

With reference to the Yogo sapphires, Kunz (1897, p. 420) wrote that the colors vary

* * * from light blue to quite dark blue, including some of the true "cornflower" tint so much prized in the sapphires of Ceylon. Others incline to amethystine and almost ruby shades. Some of them are "peacock blue" and some dichroic, showing a deeper tint in one direction than another, and some of the "cornflower" gems are equal to any of the Ceylonese, which they strongly resemble * * *

Unlike the sapphires from other Montana localities almost all the Yogo stones are blue and the color is remarkably uniform through a stone. Zoned or unevenly colored sapphires are almost unknown here, although very common in almost every other sapphire locality in the world. The Yogo stones are not as intense in color as the dark-blue Oriental sapphires, but they are almost as brilliant under artificial light as they are by daylight; whereas the Oriental stones are commonly black and lifeless by artificial light. Lilac- to purple-tinted stones are common at Yogo. Gadsden states that most of these stones were rejected as gems during sorting and sold for industrial use; eventually a few were saved for cutting and some of the dark amethyst-colored cut stones are fully as beautiful as the bright, blue gems. Gadsden also reports that only three or four gem-quality rubies (purplish-red stones) were found during some 30 years of mining.

Most of the Yogo sapphires are mildly dichroic, blue or lilac-blue by light transmitted parallel to the c axis and blue-green by light transmitted normal to the c axis. In order to evaluate the range in color of the Yogo sapphires, the writer divided a 10-gram sample of very small crystals, ½ to 2 millimeters in diameter, into four arbitrarily delimited color groups and weighed the fractions, with the following results :

| Percent | |

| Colorless and very pale sapphires | 16 |

| Distinctly blue sapphires | 60 |

| Distinctly lilac or pale-amethyst sapphires | 22 |

| Amethyst to red-purple sapphires | 2 |

This subdivision can hardly be representative of the larger stones; more than 60 percent of the uncut Yogo sapphires of several carats observed by the writer were blue and only a few were nearly colorless.

VALUE

It is difficult to place an exact value on any gem, and it is almost impossible to estimate the values assigned to Yogo sapphires at various times in the past. In general, the price of cut sapphires has shown a marked increase from decade to decade during the last half century or longer, and this increase does not appear to have been affected by the production of excellent and relatively inexpensive synthetic corundum gems. Kunz (1896, p. 909) reported that 60 carats of fine gems worth $5 to $25 a carat were cut from 200 carats of selected rough stones in 1895. Weed (1902, p. 282) reported that in 1901 the larger Yogo gems, those weighing several carats when cut, were valued at $75 a carat and that the smaller stones retailed at $30 to $40 a carat. According to Stoddard (1922, p. 170), £400 was paid in 1910 for a 10-carat rough stone which weighed 5 carats after cutting.

Industrial sapphires from the Yogo deposit were valued at $2 to $6 per ounce in 1905 according to Kunz (1906, p. 1338), who states that the Yogo material was in strong demand because the platy form of the crystals required less cutting in the manufacture of watch jewels than was necessary with crystals from other localities. Natural sapphires are no longer in demand for most industrial use, having been displaced during the last few years by synthetic corundum.

ECONOMIC DEVELOPMENT

HISTORY

The following chronologic record of the development of the Yogo sapphire deposit has been compiled from a large number of sources, many of which duplicate the information contained in others. In order to avoid citation of an excessively large number of references, preliminary acknowledgment of several general sources is given here. The volumes of Mineral Resources of the United States published by the United States Geological Survey during the period 1901–24 contain numerous brief accounts of the Yogo deposit. Somewhat similar descriptions and summaries may be found in volumes of The Mineral Industry, now published annually by the McGraw-Hill Book Co., Inc. C. T. Gadsden, manager of the British mine during most of its productive period, supplied much valuable first-hand information during the writer's visits to the deposit. Gadsden also made available a brief history of the New Mine Sapphire Syndicate written in 1925 by Francis H. Wood, president of the syndicate. Specific reference will be made in the text to the more significant published records from which information has been obtained.

About 1878 small deposits of placer gold were found in Yogo Gulch near the sapphire deposit. Most of the valleys in the region were then prospected for placer gold, and sapphires were first noted in test concentrates from the small valley in which the workings of the British mine are located. J. Hoover, a prospector, was in charge of the work when the discovery was made. The placer claims in the area were held by Hoover and three local ranchers, G. A. Wells, S. S. Hobson, and Matthew Dunn. Soon after the discovery of the placer sapphires the sapphire-bearing dike was located by another rancher, W. Ettienne (also recorded as James Ettien), who found sapphires in the earth heaped up by gophers along the trace of the dike. Ettienne made no attempt to take up mining claims when he learned that sapphires had never been produced successfully from deposits where they occur embedded in the rock. Hoover, Wells, Hobson, and Dunn eventually traced the dike eastward about a mile and westward about 2 miles. They located 10 lode claims and decided not to try to extend their holding farther west into the rough country along Yogo Gulch. The western extension of the dike was discovered by two prospectors, Sweeny and Burke, who took up six claims near the junction of Yogo and Kelly Gulches.

Hoover and his three partners met with little success in their placer gold mining, and by 1895 they had turned most of their attention to the mining of sapphires. They organized a company with $100,000 capital, and incorporated under the name New Mine Sapphire Syndicate. Wells failed in an attempt to get Tiffany & Co. to handle the sapphires, but during a visit to his old home in England in the summer of 1898 he succeeded in interesting Johnson, Walker, and Tolhurst, Ltd., who contracted to serve as sole marketing agents for the stones. Soon after Wells returned to Montana, he informed the English company that Hoover had decided to sell his interest in the venture. Brownfield Tolhurst and Edward A. Keller made a trip to America and purchased Hoover's shares in the syndicate. Wells had sold more than half of his shares during his visit to England, and in 1899 Dunn also sold his interest to Johnson, Walker, and Tolhurst and to E. A. Keller. English stockholders thus obtained control of the company, and in 1901 Hobson sold his shares to them. G. A. Wells served as president of the Syndicate until 1910. C. T. Gadsden first came from England to the sapphire deposit in the late spring of 1899 as an employee of the Syndicate; in 1902 he was made superintendent of the mining operations, and he has remained in charge of the property since that time. The British company was highly successful during its early years, and tax-free dividends as high as 30 and 40 percent were paid to stockholders on a few occasions.

Sapphire production from the Yogo deposit was valued at only a few thousand dollars per year during the period prior to 1898 when British capital was invested in the venture and a market for the gems assured. Production then increased steadily and during the period 1902–5 about 1,000,000 carats of gem and industrial sapphires valued at approximately $40,000 was produced annually. (See table 1, p. 32.) During the winter of 1902, 15 men were employed in underground mining as the new main shaft was sunk. A 9-carat stone was found that year. In 1904 the underground work consisted chiefly of driving levels rather than stoping, and production declined slightly, but improved during the following year.

Production was curtailed sharply in 1906 by an injunction prohibiting the Syndicate from emptying the tailings from the washing operations into the Judith River where, it was charged, they entered irrigation ditches and damaged the irrigated farmlands below the mine. The Syndicate finally purchased agricultural lands adjacent to the mine and thereafter demonstrated that the tailings or "slums" had beneficial rather than harmful effects on vegetation. Sterrett (1908, p. 818) wrote as follows regarding the tailings:

Instead or containing chemicals injurious to vegetation, as claimed by some of the ranchers along the river below the mine, the slums have been shown actually to improve, for raising crops, the lands on which they are turned. Analysis of the slum is also reported to show the presence of nitrates and phosphates, which are helpful to any crop growth. To test this, Mr. C. T. Gadsden, superintendent of the mine, turned the water carrying the slums over portions of the ranch land owned by the company. Oats, alfalfa, and vegetables were successfully grown, both where the slums were turned over crops already planted and where the vegetables were planted directly in thick deposits of slum. In each case vegetation was most luxuriant where the slum was thickest. The coarser sands from the sapphire washings were removed by a sand trap from the sluice ditches, where the grade was low, to keep the latter from clogging up.

A supply larger than ever before of sapphire-bearing rock was mined and treated in 1907, and production reached a new high, but declined sharply during the next three years. In 1910 new washing floors were under construction, and a prolonged drought cut down on water supplies to such an extent that washing operations had to be suspended during part of the summer season. During the year a 19-carat sapphire was found, the largest ever discovered in the Yogo deposit. A 12-carat stone was also reported. In 1911 and 1912 production was about normal for the period—approximately 90,000 carats of gem material and 440,000 carats of industrial sapphires annually. No sapphires of more than 3 or 4 carats were reported.

While the British property was being developed and exploited so successfully, the claims to the west held by American interests were also undergoing extensive development, but without similar financial success. Sweeny and Burke mined the altered dike rock on a very limited scale from small workings just west of the crest of Yogo Hill at the eastern rim of Yogo Gulch. They hauled the rock in wagons to the Judith River for washing. About 1901 the prospectors sold their claims to the American Sapphire Co., incorporated in New York with a share capital of $500,000. By 1905 the company had put in more than 2,000 feet of underground workings and was engaged in construction of a mill with a capacity of 100 tons of rock per day. Kunz (1906, p. 1338) recorded a production of 1,564 carats of uncut gem sapphires in 1905; greatly increased production was anticipated after installation of the mill. The mill was reported to be in operation in 1906, but the company was engaged chiefly in development rather than production. In 1907 the company was still raising funds by selling stock when a general depression struck the country. A few lapidaries were employed at the American mine to cut and polish the sapphires, but their work is said to have been decidedly inferior to that done in Europe. About 1909 the American company's capital was exhausted and a new company, the Yogo American Sapphire Co. was organized with a capital of $100,000 to purchase the holdings of the bankrupt concern. The new company fared little better than its predecessor, and after five unprofitable years sold its assets to the New Mine Sapphire Syndicate for $80,000. The American companies had often been forced to sell their sapphires at prices below those maintained by the more stable British syndicate, which therefore purchased the property chiefly to eliminate unfavorable competition. No further use was made of the underground workings or mill at the American mine, but a large quantity of sapphires was obtained by the British company from reworking the dumps.

In the summer of 1914 only the British company was active, and it ceased operation in August, after the war began in Europe. The Syndicate resumed restricted operations in 1915 with the washing of old dumps but undertook no new mining operations. Production was subnormal throughout the war. In 1918 the Syndicate extended its corporation period to 1938. Activities during the following year were handicapped both by a shortage of miners and other laborers and by an inadequate supply of water, which caused washing operations to cease early in August after a period of activity of about 10 weeks. In 1920, production reached a value more than five times that of the previous year. It was the highest value for any year except 1913 in spite of a reported shortage of labor and trouble with the electric separator, which caused the shipment of smaller sized stones in the concentrate for sorting in London. In 1921 production increased in value to almost half a million dollars, more than twice that of any previous year. In February 1922 a larger force of miners was at work underground, and the washing floors were being enlarged. Greatly increased production was anticipated for the summer of the following year. But 1923 brought disaster in the form of a severe cloudburst on July 26 and production for the year declined sharply to a value of only $40,645. During the next 4 years production tapered to a value of $4,860 in 1927, and in 1929 the mine was closed completely. Average annual dividends paid by the Syndicate to stockholders in the period 1901–23 was about 15 percent.

The decline in production after 1923 was caused only partly by the damage from the cloudburst. Production costs rose and a labor shortage developed as the country entered a prosperous period. Two other factors contributed largely to the final closing of the mine. One of them was the declining demand for small cut sapphires. The second and more important was increasing double taxation. About 1924 taxes on profits were said to be about as follows: English income tax, 22½ percent; American income tax, 12½ percent; Montana State tax, 5½ percent. In addition, a heavy duty was charged on all gems returned to this country for sale after cutting in Europe.

Table 1.—Sapphire production in Montana and in the United States.

PRODUCTION METHODS

Yogo sapphires were first obtained from placer deposits in small valleys that cross the dike. Later they were washed from residual deposits in the soil lying over the dike, and finally from the decomposed dike rock itself. The original discoverers, Wells, Hobson, Dunn, and Hoover, had built a long flume (fig. 2) to bring water from Yogo Creek for washing gold, and this flume supplied water for sapphire mining, first for the prospectors and later for the British company, the New Mine Sapphire Syndicate. The first workings on the dike were open-cuts from which the weathered dike rock was removed by hydraulic mining. The limestone walls were firm and nearly vertical (fig. 3) and the dike thoroughly decomposed to depths of 20 to 50 feet, so that this method was successful where the slope of the hillside was such that water might drain from the lower end of the open-cut. For mining to greater depth in the cuts, or in less weathered dike rock, the sapphire-bearing material was dug out with picks and shovels, or even broken by blasting, screened, and the fine material carted to sluices for washing. Lumps of coarse material disintegrated rather rapidly on exposure to the weather, and eventually the weathered material also could be washed in the sluices. Kunz (1902, pp. 736–737) described the mining operations of 1901 as follows:

The methods employed are a curious combination of those of the California gold workings and the South African diamond mines. As in the latter, the gangue of the gems is an igneous rock, hard below, but decomposed above, in varying degrees, to a mere earthy mass at the surface. From this last the gems are separated by washing and sluicing, much in the manner of placer gold; though because of the less density of sapphires more care is necessary, and the sluice boxes must be less inclined, to prevent the gems from being carried over the riffles. Most of the New Mine Syndicate's workings are surface openings and cuts, some of the latter very extensive. Water is carried from Yogo Creek, 10 miles distant, by a ditch and flume, with a parallel hydraulic pipe line, and a system of sluices extends all along the company's workings.

Where the rock is much decomposed the hydraulic process is employed hugely; as it becomes harder, powder is necessary to break it up, The rock is thrown out in dumps and allowed to disintegrate by exposure to the weather, as with the African "hard blue." This process requires from a month to a year, according to the condition of the material. Sometimes a stream of water is turned on the dumped rock, and the process thus expedited. When sufficiently decomposed, this material is subjected to the same washing process as the material naturally disintegrated.

Some of the open-cuts along the dike are very large. One is 700 feet long and 90 feet deep; another, called the "Blue Diamond cut" is 1,200 feet long and 50 feet deep at its greatest depth. The side of this latter cutting gives a very fine section of the dike, showing the entire gradation from the hard rock below to the soft surface condition. The former is bluish or gray, while the latter becomes brown, reddish, and yellowish, from oxidation of the contained iron * * *

In the washing the fine earth is carried away with the water, all hard lumps remaining are again thrown out on a dump to decompose further, and the sapphires, after several screenings, are picked out by hand. All are saved, the larger for gems and the smaller for watch jewels, etc. The minute and imperfect ones are crushed and used for polishing powder, sometimes mixed with diamond dust, in cutting the larger stones.

About 1898 the open-cuts at the surface were nearing exhaustion, and two tunnels were put in—one just west of the present shaft house and another in the hillside east of the valley that crosses the dike 3,000 feet southwest of the shaft house (pl. 1). The main shaft was begun in 1902. A few years later the underground workings were described as follows by Sterrett (1908, p. 818).

At present the sapphire ore is all obtained from underground workings. The latter consist of a shaft 100 feet deep with drifts in each direction from the bottom. The shaft is located in a smaller coulee or valley crossing the dike. The west drift is about 2,000 feet long and nearly 200 feet below the surface of the hill on the west of the coulee, while the level above and one of the stopes reach nearly to the bottom of the 90-foot open-cut In this hill. The east drift was carried nearly 800 feet, with stopes above at varying intervals. At one place in this drift the dike has been stoped out to the surface.

The shaft was later deepened and new levels were driven several hundred feet in each direction along the dike 250 feet below the surface (fig. 7). Gadsden estimates that approximately 200,000 tons of dike rock was removed from the main workings of the British mine before operations ceased. Most of the mining was done in the winter months when surface operations were impossible because of weather conditions. The limestone walls stand with relatively little need of support, and the dike rock was easily drilled, generally with hand augers, and readily broken with light powder charges. A mule was used to haul the mine cars underground.

Figure 7.—Longitudinal section showing approximate extent of underground workings in the Yogo Sapphire deposit.

The dike rock was dumped on a platform beside the shaft house to weather and disintegrate as much as possible before the summer washing season. The alternate freezing and thawing during the fall and spring accelerated the process. During the summer, streams of water were turned against the dumps and workmen with specially designed pitchforks tossed out the larger fragments of incompletely disintegrated rock. These fragments were allowed to undergo another season or more of weathering on the platform; piles of the more resistant boulders still remain on the old floors. The disintegrated rock and smaller fragments were washed through sluices, which are flat-bottomed wooden troughs with iron-plate floors and removable iron riffles at appropriate intervals. The riffles, which trapped the sapphires and any other heavy materials, were removed at least four times daily for clean-ups. Sterrett (1908, p. 819) described the handling of the concentrates in 1907 as follows:

The concentrates are separated in a rocker sieve into three sizes, and each grade is panned down closer over a wooden tank. The oversize left on a screen of 5/8-inch mesh is carefully examined for large sapphires before discarding. The contents of the tank in which the panning is done receive further treatment on screens of two different meshes from those first used. Sapphires are picked up by hand from the coarse sizes of concentrates before shipping.

The material that passed over the riffles included many small fragments of unweathered dike rock, and it was therefore collected in a pond behind a dam a short distance below the weathering floor. After another season of weathering this material also was washed through sluices and over riffles to a second dam, later to a third, and eventually to a fourth. Very little of the dike rock escaped disintegration under this system, and it is probable that few of the sapphires, except the very small platy crystals, were not recovered somewhere along the chain of sluices. The location of the first washing floors and of a later floor at some distance from the shaft, as well as the dams and some of the sluices are shown on the map of the deposit, plate 1.

Additional refinements in the treatment of concentrates were tried out from time to time. Gadsden designed a small, modified ball mill for gentle abrasion of coarse concentrates that contained coated sapphires which might have been overlooked in hand sorting. A screen with closely spaced rods, rather than woven mesh, was used to screen out platy crystals from the gems. An electrostatic separator was used in cleaning up industrial sapphire concentrates.

At the American mine there was no gradual evolution from simple placer mining to large-scale operation. The company proposed from the first to mine and mill large quantities of dike rock, following the practices of modern metal mining, insofar as possible. Drifts were driven along the dike in the eastern side of Yogo (Gulch) and a shaft was begun at the base of the cliff. Concerning the shaft Sterrett (1908, p. 819) wrote, "It was reported that the depth was about 100 feet early in 1908, and that the shaft was equipped with an electrical hoist capable of sinking to 1,000 feet." The shaft was eventually sunk to a depth of approximately 300 feet below the surface (fig. 7). Flowing water was encountered in a fracture zone cut by one of the lower levels, but the water ran down the drift a short distance and escaped through another set of fractures, so that pumping was never necessary.

Milling operations at the American mine in 1907 were described as follows by Sterrett (1908, pp. 820–821):

It has been found that over 50 percent of the ore removed by blasting is fine enough for milling without disintegration by weathering, The ore direct from the mine, after passing through 4-inch grizzlies, is digested with water in heavy revolving screens. The latter discharge three classes of material, the fines or slimes, which are immediately discarded, the oversize or material still in lumps, which is saved for further treatment, and the digested matter ready for sizing and concentration. The lump material is left in stock piles to weather for a period of several months, by which time it is readily digested in the revolving screens and concentrated. After sizing, the digested material is concentrated on Woodbury jigs arranged to treat three sizes, three-fourths and three-eighth inch and 6-mesh. Two jigs are run in series for safety. These jigs were handling about 75 tons in a day of seven and one-half hours at the time of the visit, though from 200 to 225 tons could be treated in twenty-four hours.

The concentrates from the jigs, in rare cases, run as high as 30 percent sapphire, 5 to 10 percent being more common. The concentrates containing the watch-jewel sizes, or culls, are treated on a Blake-Morscher electrostatic concentrator and their grade brought up to between 50 and 90 percent sapphire. The final cleaning, as with the larger sizes suitable for cutting, is accomplished by hand picking. In filling hurry orders this cleaner is of value, since it enables a large quantity of sapphire to be selected much more quickly than could be done by hand alone. On the other hand, part of the sapphire goes over with the tailings, which require more labor to pick over than the original concentrates.

The operations of the American Sapphire Company have not yet reached the capacity of the plant, since much time has been consumed in perfecting the method of concentration in use and in exploratory work in the mine. The production of sapphires suitable for cutting amounted to over 100,000 carats between April and December of 1907. In addition, several thousand ounces of culls for watch jewels, bearings, and instruments of precision, were obtained at the same time.

Freeman (1915, pp. 800–802) described the operations of the two sapphire mines and estimated that only 75 percent of the sapphires were recovered by the sluicing system at the British Mine, but that practically all of the larger stones and 95 percent of smaller stones were recovered in the mill of the American mine. Except for the statements of Freeman, there is no evidence that the milling methods were more efficient in recovering sapphires than the primitive, but highly effective, methods used at the British mine, and the milling procedure was unquestionably more expensive and complex than the sluicing. The American mine was never a financial success, and it threatened the stability of the market in Montana sapphires by forced sales of gems to immediate buyers at lower prices. Freeman reports that in August 1914 the British company purchased the claims and assets of the American concern for $80,000. No attempt was made to operate the mine or mill on the American company property following the purchase, but during the summer of 1915 Gadsden supervised the washing of the dumps at the American mine, and in the sluices recovered a quantity of sapphires valued at only slightly less than the purchase price of the whole property.

PRODUCTION AND RESERVES

Published records of production from the Yogo Sapphire deposit are summarized in table 1, page 32. From the incomplete data, the writer estimates that the total production prior to the closing of the mines amounted to approximately 16 million carats of sapphires valued in the rough at about $2,500,000. The American companies probably produced less than 3 million carats; essentially all of the remainder was produced by the New Mine Sapphire Syndicate. About 15 percent by weight of the sapphires was of gem quality, and it represented more than three-fourths of the total value. Production records indicate that the average value assigned to rough Yogo gems was less than $1.00 per carat, whereas even the smaller cut stones sold for retail prices of $30 to $40 a carat as early as 1901. About 2¼ million carats was classed as gem material. It is unlikely that these stones lost more than 70 percent of their weight in cutting. If the finished gems weighed 30 percent of the original total and had an average retail value of $30 to $40 per carat, some 675,000 carats of cut sapphires worth between 20 and 30 million dollars was obtained from the Yogo deposit.

Mining was carried to a depth of 300 feet below the surface at the American Mine, and dike rock at that depth was found to be altered and subject to rapid disintegration on exposure to the weather. The average width of the dike in all the workings is said to be 8 feet, and the known length is nearly 5 miles. About one-third of the dike rock above a depth of 300 feet has been mined out along the central 2 miles of the dike. A minimum estimate of reserves of altered dike rock is therefore considered to be about twice the amount removed, or approximately one million tons of material containing more than 25 million carats of sapphires, of which some 4 million carats are gem quality. The dike undoubtedly extends downward and to either side several thousand feet beyond the area considered in this estimate, hence a figure several times greater than the estimate given above is not unreasonable.

Small colored gems of all types have been much in demand in recent years in the manufacture of fancy jewelry in the United States, and the value of natural sapphires has continued to rise, in spite of the production of excellent synthetic stones. Therefore it appears reasonable that an American company might acquire and profitably operate the Yogo deposit, producing gems for domestic consumption. Reserves of altered, sapphire-bearing rock are large; relatively cheap methods of extraction have been evolved by the British company, and an American company would not be faced with double taxation, which has prevented reopening of the mines by the present owners. Unfortunately the existing flumes, siphons, sluices, mine workings, platforms, equipment, and many of the buildings have suffered severe deterioration, as must be expected, during two decades of idleness.

Note: PalaMinerals.com selects much of its material in the interest of fostering a stimulating discourse on the topics of minerals, mineralogy, and the mineral industry. Therefore the opinions expressed here are not necessarily those held by the proprietors of PalaMinerals.com. We welcome your feedback.